We continue a wide commercial and technical collaboration with Polish and foreign partners which results in the delivery of high quality equipment combined with elements of supervision.

We are an authorized representative of some pump making companies as well as of a company specialized in spray-out shields.

We specialize in the solution of difficult, untypical problems in commercial and industrial foreign trade.

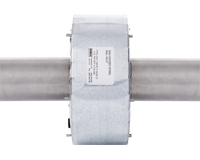

60°C.

60°C.

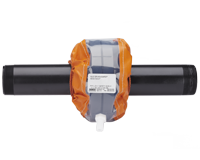

107°C.

107°C.

107°C.

107°C.

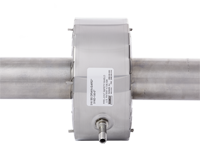

232°C.

232°C.

150°C.

150°C.

Localization of an unsealing in flanged connections.

Protection against splashing with chemically hazardous and hot fluids.

Protection against injuries and life danger for personnel.

Protection against fire and explosions.

Minimization of the so-called "Domino effect" in different sectors of the installation.

Reducing of the costs associated with the restoring of the plant to full operation.

235

235 432

432 235

235 432

432 op.pl

op.pl